Pharma

Pharma- Food

- Nutraceuticals

- Home&personal Care

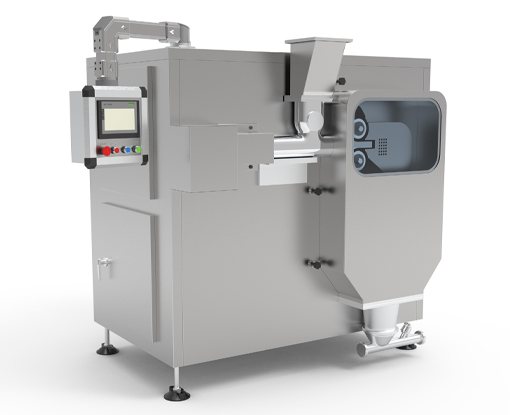

The production process is to mix the dry powder materials by the ingredients, and add them to the upper hopper by a special feeding device (pneumatic or motorized), and send them to the pressure chamber through the screw conveyor. The two high pressure pressing wheels press the material into high density slices. The density slices are granulated to the demanded size by a two-stage granulation system.

1. It adopts PLC and touch screen control, frequency converter and other systems. The speed can be adjusted freely within the specified range, and the operation is convenient and stable.

2.The advanced fault detection device will automatically protect and alarm when the working hydraulic system is abnormal or the host is overloaded.

3.The feeding structure of special stainless steel conical screw or nylon vertebra screw ensures efficient feeding.

4.The surface of the special stainless steel pressure roller is specially treated by gas nitriding technology. The surface of the roller has strong wear resistance and fatigue resistance, and has good corrosion resistance.

5.The roll water circulation cooling can be cooled by ordinary water cooling and forced cooling of the ice machine of the refrigerator to avoid the sticking phenomenon of the material.

6.The introduction of imported brand advanced hydraulic system, simple and reliable operation, high degree of automation.

7.The machine can be equipped with an oscillating/vibration sieve, water chiller and vacuum feeder.